Packing

The facilities at our production site in Ulm are oriented to the needs and preferences of our customers. As a producer of brand names (private label), we continually develop new forms of packaging and materials and implement these promptly in collaboration with our customers.

Accordingly, the expansion and modernisation of our machinery is our “pride and joy” and means that we have a leading production capacity in Europe of over 240 tonnes of raw materials and more than 2.5 million bags per day.

Fully automated and computer-controlled equipment produces

- tubular bags

- block bottom bags

- 4Seal bags

- Doypacks vertical and horizontal

with or without reseal

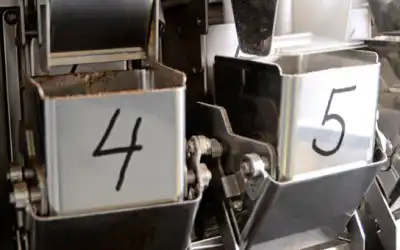

Mixed products (trail mix, mixed nuts, exotic mixes) have become increasingly popular over the last few years. In order to maintain production integrity and, thus, product quality for all consumers, we have designed and developed mixed scales with our machinery suppliers, which weigh the individual components for each bag. This means that consumers get a product of consistent and traceable quality.

Our stainless steel equipment and a high level of automation enable our staff to concentrate their efforts on safeguarding production. As a result, we are in a position to meet our customers’ continually increasing quality requirements.

Whether it’s mono-product or mixed, mono-cartons or assorted cartons for several different products, there are virtually no limits on our customers’ ideas. Commercial feasibility is down to our experience and our commitment to accept any challenge willingly.

Copyright ©

Olam International Limited. All Rights Reserved. Co Reg No: 199504676H